Major Bi-Fuel System

Components and Sub-Systems

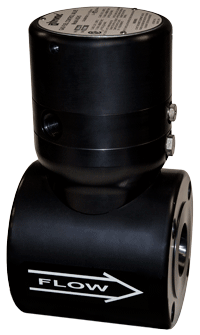

AIR-FUEL MIXER

The AGM-PV is a venturi carburetor that provides the optimal demand signal for use in supplying the required air/gas mixture to the engine. The proprietary design is manufactured to exacting tolerances from anodized aluminum for corrosion resistance and highly reliable service. Gas mixes with the incoming air stream through a slot in the inner diameter of the mixer throat. The width of this slot is adjusted by means of a collar on the outside of the mixer body. This collar serves as the fixed power valve and is used to adjust the maximum allowed substitution rate of the system. Electronic pressure sensors, mounted to the mixer, sense the pressure in the mixer plenum.

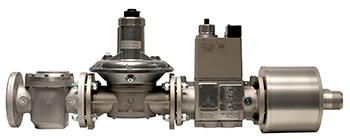

STANDARD GAS TRAIN

Conditioning and regulating the natural gas prior to admission into the engine is a critical part of the GTI Bi-Fuel system. The system "gas train" includes a 50-micron fuel filter, a manual shutoff valve, an electrically operated solenoid valve actuated in the event of an emergency or for system shutdown, and a zero-pressure, demand-type gas pressure regulator. This latter component reduces the inlet gas pressure (.5–4 psig) to roughly atmospheric pressure. With a negative outlet pressure, the design allows the system to use a "demand" control scheme whereby engine intake airflow determines the gas flow of the engine. As engine load changes, corresponding changes in intake air volume automatically draw additional fuel into the mixer.

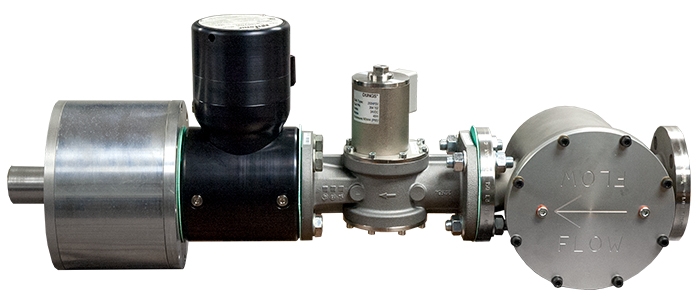

GTI+ GAS TRAIN

The GTI+ system utilizes a fully electronic, advanced gas train design, which includes the Altronic AGV5 Fuel Valve, a microprocessor-based smart valve equipped with a fast-acting voice coil for rapid and accurate response. The AGV5 serves as both the zero governor pressure controller and fuel valve to control the bi-fuel substitution rate across the engine load range. The valve res ponds in closed-loop control to an electronic pressure signal within the mixer housing, ensuring that the fuel demand at the mixer is satisfied at any given time and eliminating pressure droop associated with pneumatic pressure control systems. This closed-loop control minimizes the effects of pressure drops between the outlet of the gas train and the mixer inlet. This allows the desired substitution rates to be met, while maintaining the fundamental safety characteristics of a zero pressure draw-through design. The AGV5 is a proven design that has been utilized as the fuel control device in hundreds of gas engine applications. Its soft-seat poppet is highly tolerant of gas stream contamination and offers fail safe reliable service. Since the AGV5 is rated to a higher pressure, the gas train can accept gas supply pressure of up to 50 psig, eliminating the need to reduce higher gas supply pressures to lower gas train inlet pressures with an added primary regulator. The new enhanced gas train also uses a highly-reliable, automatic, fast-acting, industrial shutoff valve to provide dual shutoff capability. The actuator is equipped with the ability to visually confirm the OPEN/CLOSED position of the valve.

ponds in closed-loop control to an electronic pressure signal within the mixer housing, ensuring that the fuel demand at the mixer is satisfied at any given time and eliminating pressure droop associated with pneumatic pressure control systems. This closed-loop control minimizes the effects of pressure drops between the outlet of the gas train and the mixer inlet. This allows the desired substitution rates to be met, while maintaining the fundamental safety characteristics of a zero pressure draw-through design. The AGV5 is a proven design that has been utilized as the fuel control device in hundreds of gas engine applications. Its soft-seat poppet is highly tolerant of gas stream contamination and offers fail safe reliable service. Since the AGV5 is rated to a higher pressure, the gas train can accept gas supply pressure of up to 50 psig, eliminating the need to reduce higher gas supply pressures to lower gas train inlet pressures with an added primary regulator. The new enhanced gas train also uses a highly-reliable, automatic, fast-acting, industrial shutoff valve to provide dual shutoff capability. The actuator is equipped with the ability to visually confirm the OPEN/CLOSED position of the valve.

CONTROL PANELS

The Control Panels are based on proven Altronic controllers and provide state-of-the-art engine control and safety shutdown monitoring. The system is designed specifically for GTI Bi-Fuel applications and is straight-forward and easy to operate. The panel monitors a number of pressure and temperature points and returns the engine to 100% diesel operation should any parameter deviate from its normal range. In addition, an hourmeter function tracks the operating hours when in Bi-Fuel mode.

Alarms are annunciated in English-language messages (other languages can be programmed), and the controller maintains an alarm log of the last 100 events.

© Altronic, LLC